If you’re in the farming business or planning to invest in hay balers, you’re probably wondering what to look for when buying one. Whether you’re a seasoned farmer or just getting started, buying the right hay baler can make your work a lot easier and more efficient. In this blog, we will walk you through the essential features, different types of hay balers, and some helpful tips that can guide you in making an informed decision.

Hay balersare a vital piece of equipment for anyone who works with hay. They help to compress the cut hay into manageable bales, which are easy to transport and store. Understanding what you need from a hay baler is key to ensuring that you get the most value for your money.

Key Features to Look for in Hay Balers

When you’re out shopping for hay balers, certain features can make all the difference in the efficiency of your work. Let’s break down these key features and why they matter.

Size and Bale Density

One of the first things you should think about is the size and bale density. Some hay balers are designed to produce smaller, denser bales, while others may create larger, lighter bales. Depending on your needs, you might prefer one over the other.

For example, small round hay balers are great for smaller farms or those with limited storage space. These balers typically create compact bales that are easier to handle. On the other hand, larger square bales might be more suitable for larger farms where you need to produce more hay at once.

Type of Bale: Round or Square

Hay balers come in two main types: round and square. Each type has its pros and cons, and choosing the right one depends on your specific needs.

- Round Bales: These are the most common type of bales. They are typically easier to handle and can be left outside without worry, as they shed water well. Small round hay balers are popular in this category because they can produce manageable bales for smaller operations.

- Square Bales: Square bales are easier to stack and store, especially if you’re working with large quantities of hay. They’re perfect for farmers who have more space and need to store hay in a barn or other dry areas.

Durability and Build Quality

Durability is another important factor to consider. Hay balers go through a lot of stress as they work, so you need a machine that can stand the test of time. A well-built hay baler should be made of high-quality materials that can withstand harsh weather and the wear and tear that comes from regular use.

When evaluating the durability of a hay baler, it’s also important to look at the ease of maintenance. A hay baler with easy-to-reach parts will be much simpler to service when it needs repairs or regular maintenance.

Hitch Type and Compatibility

You need to make sure the hay baler you’re considering is compatible with your tractor or other equipment. Different hay balers have different hitch types, so it’s essential to check the specifications to ensure the baler will fit your tractor’s hitch system. Many hay balers have adjustable hitches, but it’s still something you should double-check before purchasing.

Different Types of Hay Balers

Choosing the right type of hay baler depends on the size of your farm, the volume of hay you need to handle, and how you plan to use the hay. Let’s take a closer look at the different types of hay balers.

Small Round Hay Balers

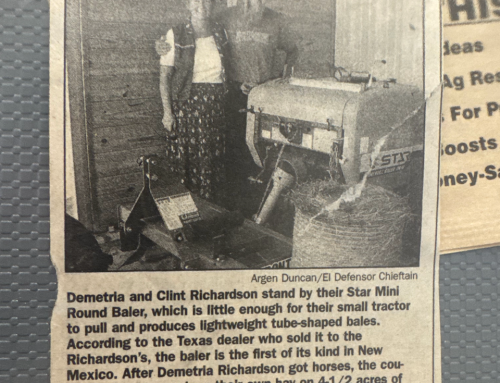

If you’re running a smaller farm or just need to bale a small amount of hay each year, small round hay balersare an excellent choice. These balers are compact and easy to maneuver, making them perfect for small to medium-sized operations.

Small round hay balers can produce bales that are lightweight and easy to move by hand or with small equipment. They’re also great for making bales that are easy to store outside, as round bales tend to shed water more effectively than square bales. These hay balers are easy to maintain, making them a good option for those who need a straightforward, reliable machine.

Large Round Hay Balers

For larger farms, large round hay balers might be the way to go. These machines can create bigger bales, which are better suited for large-scale hay production. Larger round balers are designed to be more efficient, allowing you to produce a higher volume of hay in less time. They also tend to be more durable, making them a great investment for those with high hay output.

Large Square Hay Balers

If you need to produce large quantities of hay and you have the storage space to handle it, large square hay balers could be your best option. These balers are typically more expensive but are perfect for big farms with a high need for hay. They produce square bales that are easier to stack and store, which can be helpful if you’re working in a commercial setting.

Tips for Choosing the Right Hay Balers

Now that you know what features to look for and the different types of hay balers available, let’s go over some practical tips to help you make the right decision when purchasing your baler.

Assess Your Needs

Before you start shopping for hay balers, think about your specific needs. How much hay do you need to bale? Do you have the equipment to handle large bales, or do you need something more compact and easier to move? If you’re unsure, it’s always a good idea to consult with other farmers or experts who have experience with hay balers.

Budget Wisely

Hay balers can range in price depending on the size, type, and features. When creating a budget, be sure to consider the long-term investment. You don’t want to end up with a baler that’s too small or not durable enough to meet your needs. On the other hand, don’t overspend on features that you don’t need. Stick to what’s necessary for your farming operation, and choose a baler that provides the best value for your money.

Consider the Brand

The brand of the hay baler is another important factor. Some brands are known for their reliability, durability, and customer service. When considering a brand, make sure to read reviews and do your research. Some well-known brands in the hay baler market include John Deere, Massey Ferguson, and New Holland, but there are plenty of other good options too.

Think About Maintenance

All hay balers require maintenance to keep running smoothly. Some balers require more upkeep than others, so it’s important to consider how easy it is to maintain the model you’re looking at. Look for hay balers with simple designs, as these are usually easier to service and repair.

Look for Warranties and Support

When buying any large equipment, warranties and customer support should be a major consideration. A good warranty can give you peace of mind in case something goes wrong with the baler. Look for a warranty that covers both parts and labor, and check to see if the manufacturer provides helpful customer service if you ever need assistance.

Make the Right Choice for Your Farm!

In the end, choosing the right hay baler can make all the difference in your farm’s efficiency and productivity. By considering factors like bale size, type, durability, and maintenance, you can find a hay baler that meets your needs perfectly.

Whether you’re looking forsmall round hay balersfor a smaller operation or a larger, more industrial option, there’s a hay baler out there that fits your requirements.

If you’re still unsure about which hay baler to purchase or need help selecting the best one for your farm, don’t hesitate to reach out. Contact us today, and we’ll help guide you through the process to find the perfect hay baler for your operation.

FAQs

1. What size hay baler do I need for a small farm?

For a small farm, small round hay balers are usually the best option. They are compact, easy to maneuver, and produce smaller bales that are easier to handle and store. If your farm is limited in space or production needs, a small round hay baler will be perfect for your operation.

2. Can I use a small round hay baler for large hay fields?

While small round hay balers are great for smaller fields, they may not be the most efficient for larger hay fields. If you’re working with larger areas, you might want to consider a larger round or square baler, which can handle more hay and reduce the time and effort needed for baling.

3. How long do hay balers typically last?

The lifespan of a hay baler depends on how well it’s maintained, but generally, you can expect a quality hay baler to last between 10 to 15 years with proper care. Regular maintenance, such as checking the belts and lubricating moving parts, can help extend the life of your baler.

4. Do hay balers require a lot of maintenance?

Hay balers do require regular maintenance to keep them running smoothly. Simple tasks like cleaning the machine, checking the belts, and inspecting the gears can prevent major issues. Some models are easier to maintain than others, so it’s worth looking into a baler that offers easy access to parts and routine servicing.

5. What is the difference between round and square bales?

Round bales are typically easier to handle and store outside because they shed water better than square bales. Square bales, on the other hand, are easier to stack and store indoors. The choice between round and square bales depends on your storage options and how you intend to transport the bales.