In today’s fast-paced agricultural world, 3×3 round hay balers are transforming how farmers handle and store hay. These innovative machines offer a perfect blend of efficiency, convenience, and cost-effectiveness, making them an essential tool for modern farming operations.

Why Choose a 3×3 Round Hay Baler?

- Optimal Bale Size: The 3×3 foot bales strike an ideal balance between manageability and storage efficiency. They’re large enough to reduce handling time but small enough for easy transport and storage.

- Increased Productivity: With the ability to produce up to 30 bales per hour in good conditions, these balers significantly boost your farm’s output.

- Versatility: 3×3 round balers handle various materials, including hay, straw, and even specialty crops like pine needles or maple leaves.

- Improved Storage and Transport: The uniform, dense 3×3 foot bales maximize space utilization in barns and on trucks, optimizing your storage and transportation costs.

- Weather Resistance: Round bales shed water more effectively than square bales, making them suitable for outdoor storage when necessary.

Advanced Features of Modern 3×3 Round Hay Balers

Today’s 3×3 round hay balers come equipped with cutting-edge features designed to enhance performance and ease of use:

- Net Wrapping Systems: Many models offer net wrapping capabilities, providing better bale integrity and weather protection compared to twine.

- High-Speed Pickup: Advanced pickup mechanisms allow for higher travel speeds, increasing overall productivity.

- Intelligent Monitoring: Some balers feature smart monitoring systems that provide real-time data on bale formation, moisture content, and weight.

- Adjustable Density Controls: Operators can easily adjust baling density to suit different crop types and desired bale weights.

- User-Friendly Interfaces: Modern balers often come with intuitive controls and displays, making operation simpler and more efficient.

Maintenance Tips for Your 3×3 Round Hay Baler

To ensure your baler operates at peak performance, consider these maintenance tips:

- Regular Inspections: Check for loose bolts, damaged parts, and proper lubrication daily.

- Clean After Use: Remove crop residue after each use to prevent buildup.

- Follow Lubrication Schedules: Adhere to the manufacturer’s recommended lubrication intervals.

- Off-Season Care: Clean thoroughly and store in a dry place when not in use.

- Timely Repairs: Address any issues promptly to prevent more significant problems down the line.

Comparing 3×3 Round Balers to Other Options

While 3×3 round balers offer numerous advantages, it’s essential to consider how they stack up against other baling options:

- Round vs. Square Balers: Round balers generally offer better weather resistance and are often preferred for outdoor storage. Square bales, however, may be easier to stack and transport in some situations.

- Variable vs. Fixed Chamber: Some 3×3 round balers feature variable chambers, allowing for adjustable bale sizes, while fixed chamber models produce consistent bale sizes.

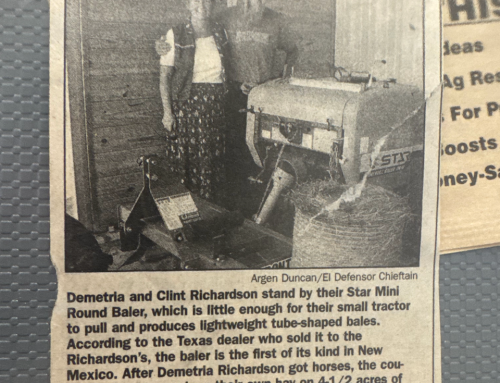

- Mini Balers vs. Full-Size: For smaller operations, mini round balers might be a more suitable option, offering similar benefits on a smaller scale.

Invest in Efficiency with 3×3 Round Hay Balers

Investing in a 3×3 round hay baler can significantly improve your farm’s efficiency and productivity. By producing uniform, dense bales that are easy to handle and store, these machines offer a practical solution for modern farming operations of all sizes. As you consider upgrading your baling equipment, weigh the benefits of 3×3 round balers against your specific needs and farm size to make the best decision for your operation.